Installing screed floor boards is an expedient measure for the renovation of property. Good insulation of the attic provides outstanding thermal protection which reduces energy costs. The screed floor board has thermal as well as sound insulation properties and immediately turns your attic into an accessible storeroom.

Application:

The Frinorm type SSP and LSP screed floor boards are suited for insulating screed and attic floors in new and renovated buildings.

Properties:

- Excellent thermal insulation values of up to 0.15 W/m²K

- Thermal insulation and a solid, permanent floor in one step

- Can be walked on and subjected to loads immediately

- Two types of thermal insulation boards: with expanded rigid polystyrene foam (EPS) or expanded rigid polystyrene foam with graphite additive (EPS lambda)

- Element thicknesses of up to 196 mm can be produced

- Chipboard, classified for load-bearing purposes in damp environments

- Dimensionally stable and non-warping

- No thermal bridges

- Flush surface, perfect board joins

- Handy format, lightweight

- Simple and fast installation, also suited for DIY installation

Product description:

| Cover panels |

Chipboard P5, 16 mm |

| Insulation |

EPS, 15 kg/m³ or EPS lambda, 20 kg/m³ |

| Thickness |

76, 86, 96, 106, 116, 126, 136, 146, 156, 166, 176, 186, 196 mm |

| Sizes |

1180 x 610 mm (0.719 m²) |

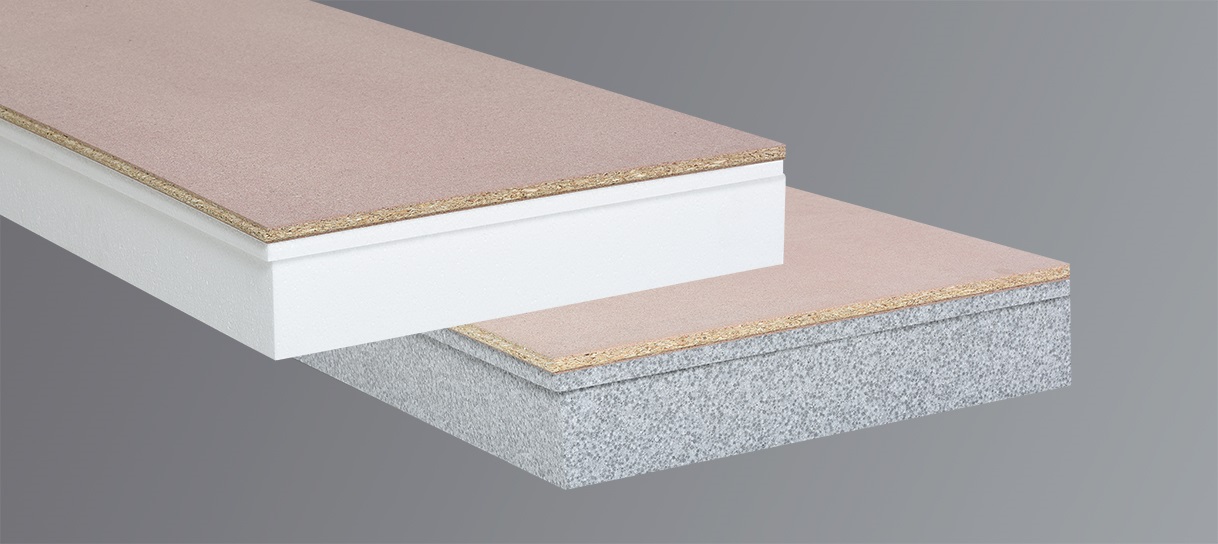

The Frinorm screed floor boards are available in different designs: type SSP is made of expanded rigid polystyrene foam (EPS), 15 kg/m³, while type LSP consists of expanded rigid polystyrene foam with graphite additive (EPS lambda), 20 kg/m³. Both types of screed floor boards are covered with a 16 mm thick chipboard P5 for load-bearing purposes in damp environments. The circumferential groove and tongue joint in the chipboard ensures closed board joins, and the circumferential rabbet in the thermal insulation prevents thermal bridges. The handy and lightweight screed floor board is installed loosely without any further fastening material. Through the application of this composite element, two results are achieved in one step: thermal insulation and a solid, permanent floor that can be walked on and subjected to loads immediately. Also suited for DIY installation.